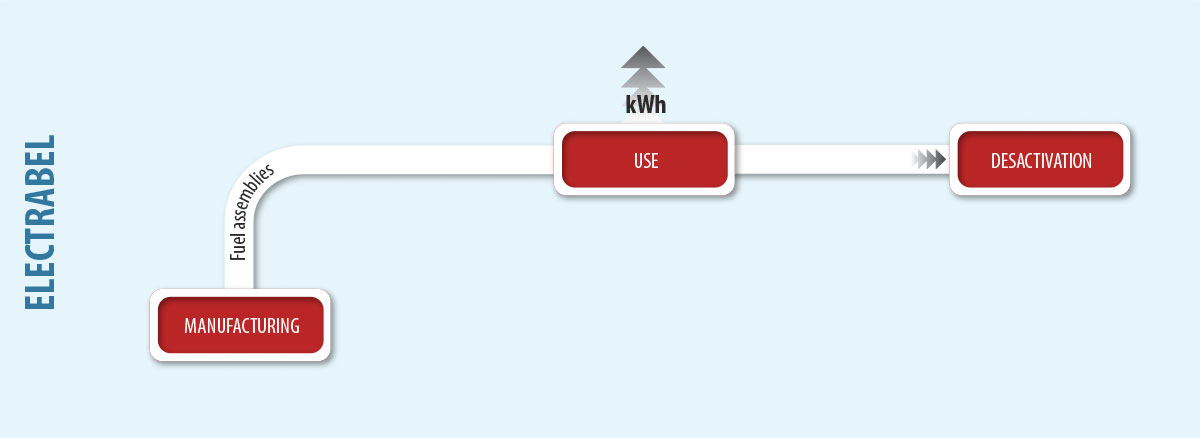

The responsibilities of the operator

Fuel assembly production

In the assembly production plant, the enriched UF6 is transformed into uranium dioxide (UO2).

This black powder will be compressed into small pellets baked in a furnace at 1,700°C to give them their final solidity and density. Each pellet has a diameter of approximately 8 mm and a height of around 13.5 mm and weighs some 8 grams. A single pellet can release the same amount of energy as a tonne of coal.

The pellets are then integrated into airtight metal sleeves called rods.

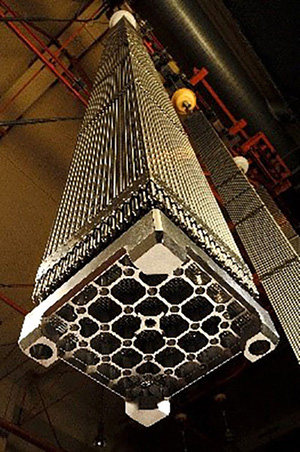

In all, 264 rods will then be mounted in a metal structure to form an assembly.

The Tihange and Doel 3 and Doel 4 reactors each have a core comprising 157 assemblies. By contrast, the Doel 1 and Doel 2 reactors have 121 assemblies in their core because they have a different level power which can be developed.

Delivery of new fuel assemblies to Tihange Nuclear Power Plant

After production, the fuel assemblies are taken by truck to the Doel and Tihange nuclear power plants, depending on requirements.

Once they have arrived at the relevant power plant, they will be kept in dry storage in sealed racks in the nuclear area of the unit involved.

Use in the reactor

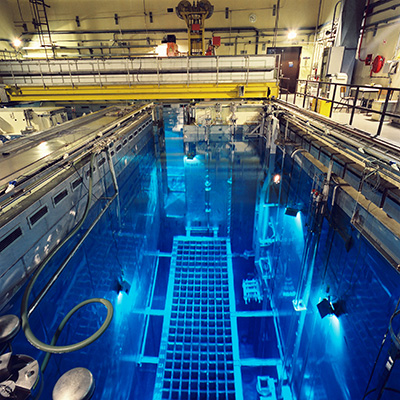

A little while before they are accommodated in the reactor core, the new fuel assemblies are transferred to the spent fuel pool and submerged in the water there. They are then integrated into the core when the reactor is shut down for a fuel reload.

Each assembly is then housed in the reactor vessel for between 12 and 18 months, with the period varying depending on the unit in question.

This means that one quarter and one third of the assemblies respectively are removed from the reactor core for a final time whenever there is a shutdown for a fuel reload.

Desactivation

Following the three or four cycles, the assembly is finally removed and is stored underwater in the unit's spent fuel pool for three to five years.

Spent fuel pool at Doel 4